About Expera

- Home

- About

Expera is the fastest in the nation as far as production is concerned.

About

Expera

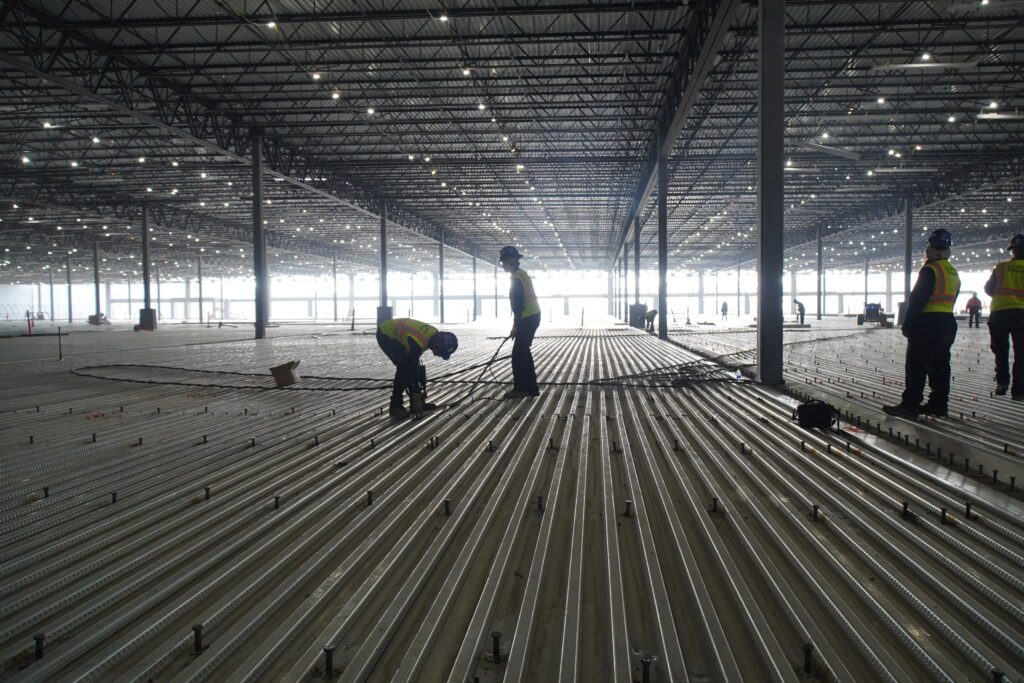

Expera installs studs and fasteners for major warehouses in the US.

Companies choose us because our efficiency and speed can’t be matched by our competitors. Our staff are high-performing and always conform to industry standards. We strive for perfection in our services and never compromise on quality. At Expera, we finish the project ahead of schedule without sacrificing quality and precision. Our team is trained to be detail-oriented. Every job is done right the first time, and we don’t risk standard and accuracy. Our commitment to excellence can’t be matched by other stud welders and deck fasteners. We know how stud welding is important for your business.

About Stud Welding

Granted, most of our visitors will be contractors searching for job site stud welding services. They have a project and a purpose. But what about the contractor who wants particulars, the searcher who must have details, and the randomly curious? Here we’ll give more information on stud welding and how the process works.

Stud Welding attaches a metal stud or rod to another metal surface, using the stud as an electrode. The weld is made from one side of the base metal and leaves no mark on the opposite side. A split second is all it takes to form a weld that is stronger than both the stud and the base metal. The stud may be a smooth bolt for anchoring, threaded for attachments, or specially shaped for other applications. The stud then functions as an anchor for mounting, a connection to other parts, or making a solid connection between metal and concrete.

The construction industry was one of the first to adapt and expand the scope of the stud welding technique. Steel buildings and bridges incorporate stud welding as a fast, strong, and cost-effective method for anchoring concrete to the framework. Stud welding can be applied for a variety of metals, including mild and carbon steel, stainless steel, copper, and aluminum. It is also used for a wide range of metal thicknesses. Thin metals usually utilize Capacitor Discharge (CD) stud welding, while Drawn-Arc stud welding is applied for thicker materials and for metals that are not in pristine condition.

Stud welding has not become automated in the construction industry, so technicians manually weld each stud into place. It is physically demanding work. Our technicians are dedicated to quality and efficiency. They are able to streamline the stud welding process individually by quick and efficient handling of each stud, and as a team through cooperation, innovation, and exceptional teamwork. After consulting the structural drawings, ferrules are laid out on the deck to mark each stud weld location. Studs are then placed within reach of each ferrule, and a technician moves along the section making the row of welds.

The weld solidifies within seconds, and then the ferrules are broken off. Each stud is then tested for solidity by striking it with a sledgehammer. Our technicians listen to the sound produced and can quickly identify a faulty weld. Quality control testing is performed by bending a stud over 35 degrees. Stud welding produces a weld that is stronger than the stud and the base material, so the weld does not crack when the stud is bent. Two studs in each section are tested in this way to ensure quality throughout the structure. Our technicians have an extremely low stud failure rate. This increases our team’s production rate, as it is time-consuming to re-route cable to replace defective studs.

Stud Welding revolutionized the shipbuilding industry after the process was developed by Nelson during the 1930s. Stud welding eliminated the time-consuming practice of drilling holes through steel decking and hand-welding studs from underneath to secure the wood decking. Stud welding is still referred to as Nelson welding. Today stud welding is used in thousands of applications in every major industry throughout the world, from the shipbuilding and automotive industries to manufacturing everything from electronics to catering equipment. Most stud welding is completely automated, and studs, bolts, and fasteners are precision placed by robotic welders.

Before job site work can begin materials and equipment are transported to the job site. Many large warehouses have five levels and require half a million studs. Often, these projects are completed in record time, requiring not only fast work but the continual moving of equipment to reach more areas and to accommodate other construction on the site. Generators and welders are set up and cable is laid out to reach the welding location. Cables are stretched to reach every square foot to be stud welded. This is often quite some distance in order to reach the far corners and upper floors of the building. The welding current, weld time, stud gun adjustments, and other settings are made, determined by the welding materials and conditions.

A stud is loaded into the end of the stud gun, then the end of the stud is placed in the center of the ferrule and pressed down against the decking. When the stud gun trigger is squeezed, the stud lifts slightly and an electric arc passes between the stud and decking. The intense heat instantly creates a pool of molten metal, and the stud is automatically plunged down into it and fuses to the parent metal. The weld fully penetrates the decking and into the beam below within a second. The ferrule confines the molten pool and shapes the weld around the base of the stud. The process is complete for that stud and the technician moves on the next. The welding process is so short that the technician’s time efficiency makes the difference in quick installation.

The Sequence

A stud is inserted into the stud gun.

The stud is placed within the ferrule.

The stud is pressed against the decking.

An electric arc initiates the weld.

The stud is plunged into the pool of molten metal.

The weld is instantly fused.

Finished weld. The ferrule can now be broken off and discarded.

Quality control testing. Every stud is sounded to ensure a solid weld.

Expertise to Perfection.

The Challenge

Since we began stud welding, we have experimented with hundreds of ideas to improve our production and efficiency. Along the way, we encountered all the usual challenges…and because of the production speed we were reaching, we ran into all sorts of unusual problems as well. We were pushing our equipment to the limit. Cable attachments overheated. Equipment wore out. We needed faster and more ergonomic solutions for moving tools and equipment.

Connection Kit

This kit contains everything you need to increase the longevity of cable end connectors by removing and preventing oxidization.